Energy Saving Technology

We communicate closely with our customers enabling them to make the most effective use of finite energy resources. Naigai Industries offers equipment solutions customized for customer specifications and site environments. The burner system with secondary-air supply pipe, our proprietary technology, is a highly acclaimed energy-saving solution, which is adopted by many customers for their baking ovens.

The Secondary-air Supply Pipe Burner (Our company’s proprietary technology)

In a typical burner used in a bread making oven, 90% of the air required for stable combustion is pre-mixed (primary air), while the remaining 10% is the air around the burner (secondary air) .

However, when the oxygen in the oven is consumed by gas combustion, the inside of the oven is gradually filled with carbon dioxide and steam.

With a secondary air pipe, air is supplied directly to the flame. Without it, if the inside of the oven is out of oxygen, the flames will have greater length and will be weaker. By using air supply, the flame will be shorter, the fire will be completely burned, and the heat will be increased.

Burner system with secondary-air supply pipe in video

The 3-section burner

A selector allows switching between the front (near), middle (center) and tip (far) sections of ribbon-type pipe burners so that the flame intensity can be changed.

You can select the firepower with the selector (3-section type) attached to the burner. This is used to change the firepower because the baking degree of the bread may change between the middle and both ends of the conveyor.

① Higher power in the near section

② Higher power in the center section

③ Higher power in the far section

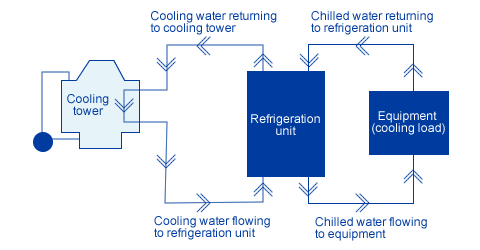

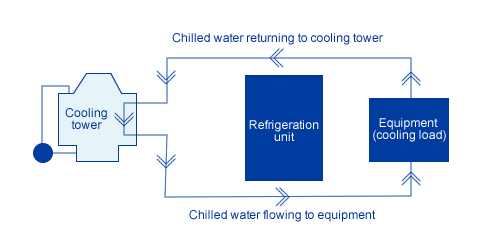

Free Cooling System

This is a system to produce chilled water during the wintertime using a cooling tower that also functions as a refrigeration unit in summer. It utilizes the natural cold air of winter, without run a refrigeration machine, to produce chilled water production. If the required temperature of the water is relatively high, the system can serve for a longer period during the year, which helps to save more energy.

Water Treatment

Given the vital significance of water resources for humankind. Naigai Industries is committed to giving the highest priority to conservation of the global environment and promotion of chemical-free, water treatment methods. We offer water treatment systems that minimize problems associated with water quality and the surrounding environment and that keep the circulating water of water-cooled equipment and chillers in good conditions. This maintains the continued high performance of the equipment for an extended period, the maintenance and management of heat exchangers being crucial for consistent product quality and cost reduction.

Closed Pipeline Networks

Using closed pipelines reduces the number of pump heads, which lowers electricity cost. When planning the installation of large-scale, open facilities, a significant saving can be made on electricity for water transportation by adopting a closed pipeline network. We offer services in planning and installing closed pipeline networks in new facilities. We can also recommend improvements on existing facilities. Our past cases suggest that the payback period for facility improvement costs is less than one year.

Use of Vaporization Heat

Inappropriate ambient temperatures in the workplace can be physically stressful for operators. We offer solutions for improving workplace temperature control. Equipment that utilizes vaporization heat can, depending on environmental conditions, reduce employee heat stress at a fairly low cost.

Saving Energy and Reducing Cost

Drawing upon our extensive experience, we offer a full range of services from (1) reviewing current conditions of customers’ sites, analyzing data, planning, designing and installing our solutions to (2) verifying that the operation is achieving energy saving and cost reduction in production processes. In this way, we support customers’ efforts to protect the environment and ease the very challenging business conditions they face.

Contact Us

For detailed information about our products and services, please contact us using our inquiry form.