Baking and Confectionery Equipment (Gas-fired ovens)

Naigai Industries’ original burner system with secondary-air supply pipe garners high acclaim in the bread-making and confectionery industries. We keep evolving this technology to achieve ever higher performance.

Direct-fired Gas Ovens

Tunnel ovens

Our flagship direct-fired gas tunnel oven was developed to perform a wide range of baking tasks, characterized by high energy efficiency and easy operation. Each unit is made to customer specifications, including the unit size and performance capacity.

Variable baking capacity

Our baking ovens are highly responsive to temperature settings, making it easy to configure temperature zones and to control internal humidity levels by the use of the damper feature. They are versatile in terms of baking modes, from low-temperature baking over a long period of time to high-temperature quick baking, depending on the type of bread.

Easy to operate

The oven can be operated safely and properly by following simple procedures. The graphic display panel makes it easy to keep track of information such as operational status and alerts.

Burner systems

The system features high-performance pipe ribbon burners that can efficiently burn natural gas, liquefied petroleum gas (LPG) and other fuels.

Reel Ovens

Market expectations for food manufacturers are increasingly diversifying. Naigai Industries’ reel ovens are designed to simultaneously bake small quantities of different products. They can also turn out large quantities of a single type of product. This reliable equipment supports the efficient mass-production of high-quality products under variable operating conditions.

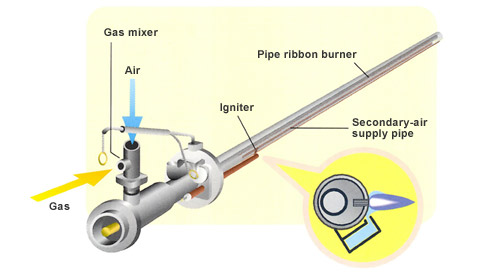

Pipe Ribbon Burner

The Naigai Industries’ pipe ribbon burner for bread and confectionery ovens commands the largest market share in Japan. We offer three types of ribbon burners for different uses: a standard model, two-section model and three-section model.

Burner System with Secondary-air Supply Pipe (Naigai Industries’ proprietary technology)

This system supplies secondary air to each burner individually, thereby ensuring complete and constant combustion. Exhaust control in conventional ovens has focused on simply discharging combustion exhaust, with less attention on ventilation associated with product quality. Our system, however, accounts for venting in order to ensure high product quality by minimizing combustion exhaust. The outstanding features of this burner system include greater energy saving, environmentally sound operation and excellent internal humidity control. A flame detector built into each burner enables the operator to monitor the combustion status of all the burners, status is displayed on the operation panel for greater safety.

Advantages in Introducing the Burner System with Secondary-air Supply Pipe

Energy-savings—improved fuel efficiency by 5 to 15%

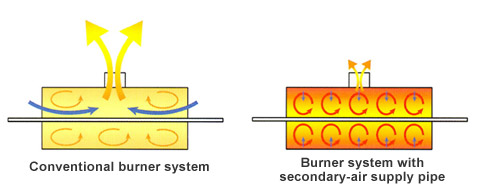

A conventional tunnel oven combustion system takes in secondary air required for combustion from inlets, outlets or other openings in the equipment. By contrast, the burner system with a secondary-air supply pipe reduces the overall air intake by directly feeding secondary air to each individual burner. Since this system does not rely on the ambient air, it minimizes exhaust emissions, which in turn reduces the heat loss due to venting and thereby improves fuel efficiency.

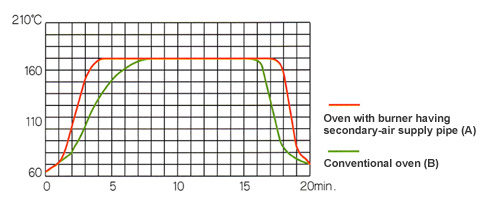

Baking efficiency

The chart shows the temperatures inside the baking chamber measured at different positions between the oven’s inlet and outlet. The oven with the burner having a secondary-air supply pipe achieves the preset temperature faster than the conventional oven, demonstrating a higher baking efficiency (data source: Naigai Industries, Inc.).

Environmental performance—significantly reduced CO2 emissions

The system benefits from the secondary-air supply pipe, which feeds only the amount of air required for combustion. This facilitates full consumption of the combustion air, resulting in reduced CO and NOx emissions for safer operations. With a reduced need for venting, the burner system consumes less gas, saving up to 15% of the fuel. This also contributes to the mitigation of CO2 emissions.

The system therefore contributes to reducing environmental impact—an increasingly important good for all companies.

Temperature distribution—smaller temperature differential inside the chamber

Conventional ovens produce a large amount of exhaust which must be compensated by intaking cold ambient air from inlets and outlets. The air current constantly generates uneven temperature distributions inside the oven chamber. The use of a secondary-air supply pipe reduces the need for venting, producing a positive internal air pressure. This contrasts with the negative air pressure inside conventional ovens. This enables finer control of the air temperature in different zones inside the oven.

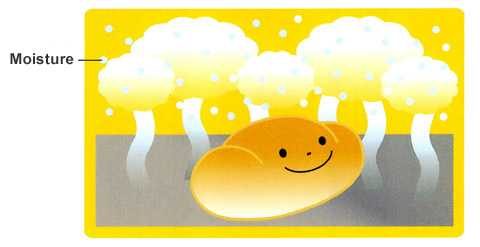

Humidity control—easy humidity level control inside the chamber

The exhaust suppression effect allows moisture generated by the product as well as by gas combustion to be retained in the oven, enabling control with humidity as a parameter.

Constant-temperature Water Flow Control System

A perfect match for mixers for bread/confectionery-making

This system allows easy preparation of the water for bread dough. Conventionally, it is prepared by blending chilled and hot water. Our water flow control system, on the other hand, achieves constant-temperature water by heating prepared chilled water (about 2-7°C) or tap water with hot steam, greatly improving control accuracy while reducing energy and space requirements.

The system can feed several mixers, and with a touch-sensor control panel, it is very easy to configure water temperatures and flow rates.

Compact design

Duct diameter: 25A / W: 1,100 / H: 1,650 / D: 600 (mm)

Duct diameter: 40A / W: 1,200 / H: 1,800 / D: 800 (mm)

Specifications

- Range of flow

- 7-41 liter/min (dia. 25A)

10-60 liter/min (dia. 40A)

- Range of temperature control

- Chilled water to 45°C

- Volume measuring accuracy

- ±0.5%

- Temperature accuracy

- ±0.5°C

- Power source

- 1φ, 100/200V, 300VA

- Supply steam

- 0.4 MPa / up to 210 kg/h

- Supply air

- 0.4 MPa / 100 L/h

Our performance in this business area

- Bread manufacturer’s plant (Hiroshima prefecture)

- Delivered direct-fired tunnel ovens

- Bread manufacturer’s plant (Saitama prefecture)

- Delivered a constant-temperature water flow control system for bread dough preparation

- Bread manufacturer’s plant (Saitama prefecture)

- Updated the air-conditioning system of their fermentation room

Contact Us

For detailed information about our products and services, please contact us using our inquiry form.