The Naigai Way

Moving forward with a relentless drive for technological development and customer engagement

The heart of our work is to develop production lines

for customers through close communication with them,

pursuing technological advances relentlessly to deliver

the quality that our customers demand.

Stand Right By Customers as Their Reliable Partner

ATTITUDE

Since the company’s inception in 1947, we have been trusted by food manufacturers who enjoy our full line of services from designing to implementing and servicing their production equipment. Our sound growth owes to the experience gained through these direct engagements. Therefore, our customers’ trust and confidence in us is the very essence of our foundation. We continue to nurture our customers’ trust and confidence, delivering quality and value with which they can advance their businesses.

Our comprehensive services deliver value only we can offer

- Research

- Planning

- Design

- Installation

- Pilot run

- Maintenance

Be Present at Production Sites and Obtain Deep Insight into the Production Lines

BELIEF

One of our important precepts is “to observe the customers’ sites in person and pay attention to what they say to us.” We have developed new technology so often through our close engagement with customer production lines, where we are inspired and enlightened. With unceasing humility, we approach our customers’ production sites and learn from what they tell us. We mobilize our creativity and engineering competence to the full extent for continuous improvement.

Our major work delivered to mainstream manufacturers

Container plants

Food manufacturing plants

Cogeneration

systems

Unrelenting Quest for New Technological Frontier

TECHNOLOGY

Technology in the food manufacturing industry is constantly evolving, expanding the scope of its challenges from food safety to the reduction of environmental impact and improved energy efficiency. We do not allow ourselves to be content with the technology available today—we always explore new technology that delivers value to customers’ production sites to the extent that we are not afraid of rendering the current technology obsolete by our hands. The progressive technology that arises from such efforts is a priceless asset for us.

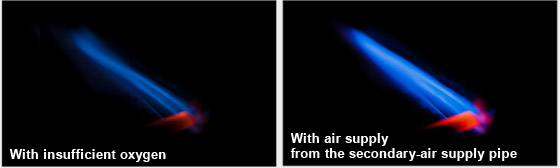

Technological innovation brought about by the burner system with secondary-air supply pipe

The burner system with secondary-air supply pipe is Naigai Industries’ original technology, chosen by many customers, including major food manufacturers in Japan and other countries in Asia. The strongest feature of this burner system is the flexible and precise control of temperature and humidity levels inside the oven chamber. It not only improves the quality of finish products, but also makes significant energy saving by ensuring complete combustion in the oven, reducing the gas consumption by up to 15%, and thus lowering CO2 emissions.

This unique mechanism delivers secondary air directly to the individual burners, realizing consistent and complete combustion. As the oxygen inside the oven chamber is consumed through the combustion reaction, the lack of oxygen dampens the gas combustion power (left image). The secondary-air supply pipe delivers the necessary air to ensure complete combustion and boost the combustion power (right image).

Committed to “One Person One Project” style

SYSTEM

It is a common practice among engineering companies to divide tasks and responsibilities between different divisions, such as sales and engineering. We at Naigai Industries have chosen to take a different approach: one engineer is assigned to a project, to be in charge of it from the start to the end. Our engineers proudly call this system “One Person One Project.”

Model cases with major outcomes

Satisfying Evolving Customer Needs in Diverse Fields of Expertise

DOMAINS

All Naigai Industries offices and group companies in Japan are ISO 9001, ISO 14001 and ISO 45001 certified.